PWM (Pulse Width Modulation) Explained: The Heartbeat of Modern Electronics

When we talk about modern electronics—from washing machines and fans to Arduino robots and LED lights—there’s one silent hero working in the background: Pulse Width Modulation, or PWM.

PWM is a digital technique used to mimic analog control. It allows devices to vary speed, brightness, and power with high precision, while still being energy-efficient. Think of PWM as the heartbeat of digital control in hardware systems.

In this blog, we’ll dive deep into:

-

What PWM really means

-

How PWM works with visuals

-

Why it's better than analog methods

-

Where it's used in real life

-

How Arduino implements PWM

-

Advanced uses in BLDC motor control

-

Limitations and design tips

1. The Core Concept of PWM

Imagine a light switch being flicked ON and OFF 1000 times a second.

Now imagine you keep it ON for 70% of the time and OFF for 30%.

Even though it’s switching rapidly, your eyes perceive a dimmer light—not because voltage dropped, but because the average power delivered is lower.

This is PWM in action.

PWM controls average power by switching digital outputs ON and OFF rapidly.

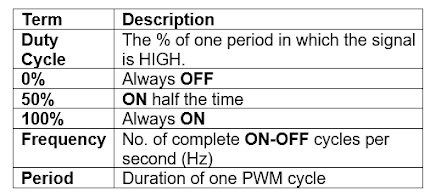

2. Essential PWM Terminologies

Duty cycle

3. Why PWM Beats Traditional Analog Control

Analog methods like using resistors to reduce voltage result in energy being wasted as heat. PWM offers a far better solution:

-

Highly efficient (less heat loss)

-

Digital-compatible (perfect for microcontrollers)

-

Fine-grained control

-

Ideal for battery-powered devices

That’s why PWM is embedded in most electronic appliances today.

4. Real-Life Applications: PWM in Action

1.Washing Machines

PWM signals control:

-

Drum Motor Speed – smoother acceleration and deceleration

-

Water Heater – temperature regulation using controlled bursts of power

-

Solenoid Valves – precise water flow management

2.Lighting

-

Dimming LEDs without flicker by adjusting the duty cycle

3.Fans

-

Noise-free speed control for better comfort

4.Arduino Projects

-

Servo motors

-

Buzzer tone control

-

RGB LED fading effects

5. Visualizing PWM – Duty Cycles in Action

Example of an Arduino Code Example for PWM

void setup() {

pinMode(9, OUTPUT);

}

void loop() {

analogWrite(9, 127); // 50% duty cycle (range: 0-255, 0 - LOW , 255 - HIGH)

}

Arduino uses analogWrite() to generate PWM on specific digital pins. The default frequency is around 490 Hz or 980 Hz, depending on the pin.

7. Hardware That Generates PWM

PWM is generated through hardware timers in embedded systems. Here’s where you’ll find them:

-

Microcontrollers like ATmega328P (Arduino)

-

Motor drivers like L298N, DRV8833

-

Inverters and SMPS for power conversion

-

Digital Signal Controllers

These ensure accurate, low-jitter PWM output for mission-critical tasks.

8. Advanced PWM Use: Inverters & BLDC Motor Control

In complex appliances like washing machines, PWM works with:

-

MOSFETs/IGBTs to switch high current

-

Feedback sensors like Hall effect sensors

-

PID control loops for torque and speed optimization

This setup allows:

-

Smooth motor start-up

-

Variable-speed cycles

-

Energy-efficient laundry operation

9. Limitations and Design Tips

While PWM is powerful, it does come with challenges:

-

EMI (Electromagnetic Interference) due to high-frequency switching

-

Audible noise in motors and inductive loads

-

Needs filtering to simulate analog output (low-pass filter required)

Pro Tips:

-

Use capacitors to filter PWM for smoother signals

-

Increase frequency to avoid buzzing (above human hearing ~20kHz)

-

Shield cables to reduce EMI

Mastering PWM = Mastering Control

PWM isn’t just a topic for electronics textbooks. It’s how your gadgets breathe—controlling motors, lights, pumps, and more with incredible finesse.

Whether you're automating a fan, fine-tuning a motor, or making an Arduino light dance—PWM is your best friend.

So next time your washing machine runs a silent, smooth spin—know this: it’s all because of millions of tiny ON-OFF pulses.

Stay tuned with Hobitronics – where electronics comes alive!

Comments

Post a Comment